DGNB Blog all about sustainable building

written by Pia Hettinger

Buildings contain a lot of material. These in turn are valuable resources that are becoming increasingly scarce and are responsible for many CO2 emissions. Structural engineers can counteract this consumption of materials on a massive scale. At least that is how professor Patrick Teuffel sees it. We spoke with him about built heavyweights and the current state of research in the world of materials.

Pia Hettinger: Professor Teuffel, you are working as a structural engineer. What is your role in the construction process?

Professor Patrick Teuffel: Basically, we are responsible for ensuring that the building has a well-designed, economical and appropriate load-bearing structure and that it is sustainable in the end. We deal with everything that has a supporting function: walls, ceilings, pillars. In doing so, we are in exchange with the architects or even the building services planners. What role we take on in detail naturally depends on the construction task. A bridge requires different planning than an exhibition hall or a tower. In principle, however, we should be involved from the very beginning for an integrative and thus optimal planning, i.e. right from the interdisciplinary planning competition. Unfortunately, this is often not the case in reality.

Why should structural engineers in particular take their role as sustainability representative seriously?

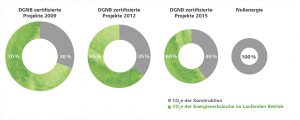

For a long time, the debate about sustainability in construction was primarily about saving energy. But the big issue of today and tomorrow is the consumption of resources and the associated CO2 emissions as well. Since 80 to 90 percent of the resources are used in the shell of a building, i.e. in the foundations, ceilings, columns, walls, etc., the structural engineer has many opportunities to act in the interests of sustainability. The mass is in the supporting structure. With the necessary knowledge and appropriate advice we can reduce this on a big scale.

The relative share of CO2 emissions from grey energy is increasing compared to the emissions from energy consumption during operation. © DGNB

So this means that our buildings are absolute heavyweights.

The majority are. A few figures make it clear to us what kind of masses we are talking about in construction. Even today, most buildings in Germany consist mainly of reinforced concrete. Take a normal residential building with two floors. A 20-centimeter thick concrete ceiling weighs 500 kilograms per square meter. On top of that, it is estimated that about 50 percent is used for columns, walls and other building components. An ordinary residential building therefore already weighs several 100 tons. Now think about the enormous impact of saving a few centimeters per floor slab or wall. By the way, a study by the Institution of Structural Engineers: “How to calculate embodied carbon” showed that a structural engineer can save an average of 200,000 kg CO2e per year if the focus is on sustainable structural design.

So should we basically build as light as possible or is it sometimes worth another ton?

Lightweight construction is of course an obvious way to save resources. The Olympic Stadium Munich, for example, is symbolic of lightweight construction. These membrane and textile constructions work wonderfully as stadium roofing, but of course not for a floor slab in a ‘normal’ building. It has to carry a lot of weight and should not deform significantly. But here, too, we could certainly build lighter if we took advantage of the unused potential of optimisation to save materials. In practice, the utilisation of components often amounts to only 80 percent, even though 100 percent would be feasible. With simple optimisation studies, we could certainly achieve material savings of 10-20 percent without any problems. Structural engineers could do much more educational work in this area. But these studies naturally cost time and money and are not (yet) shown in the work phases of the “HOAI”. Too much caution and ignorance thus provide for unnecessary material consumption.

Which other possibilites are there besides weight reduction in order to protect our resources?

There is great potential in reuse at the material, component and building level. In terms of sustainability, wood is a promising building material at first sight: it is light, has a good CO2 balance compared to other building materials and is renewable. Various current projects show that wood also has great potential for skyscrapers. But wood is not infinitely available and also not completely cheap. Therefore we must also consider other alternatives and steer in the right direction. With conventional building materials, steel, for example, is easy to recycle. And when it comes to concrete, you can use recycled concrete, because the quality is in no way inferior to normal concrete. The problem here still lies in delivery and availability.

With regard to the reuse of components, there are already valuable research approaches. At Eindhoven University, for example, we are working on how to reassemble prefabricated reinforced concrete elements from empty office buildings into apartments. Looking at the building as a whole, the potential for conversion or even unmixed deconstruction should be taken into account during planning. The DGNB has developed its own DGNB certificate for this. At the university, we conducted a study on the conversion potential of existing buildings that can help owners make important decisions. After all, they are often faced with the question of what to do with their aging building. There is still a lot of catching up to do here.

You are teaching in the area of “Innovative Structural Design”. What is behind it and where do we stand in materials research?

What’s special about our department is that, unlike chairs such as solid construction, steel construction, timber construction and aluminum, it’s not limited to one material. Instead, we research innovative materials. One focus is the application of smart materials. This is illustrated by a prototype that we are currently testing in our laboratory: We simulate earthquakes on a three-story building and vary the stiffness of materials and thus the dynamic behavior of the structure. Smart Materials can change these and thus react adaptively to the earthquake. This allows for less material to be used.

Endures day and night: The bio-based pedestrian bridge at the TU Eindhoven is in brisk use. ©Tom Veeger

The 14-meter-long bridge in Eindhoven is made of renewable materials. Here you can get more background information on the design, production and ongoing in situ monitoring: ©TU/e

Another key area for our future lies in the use of bio-based materials such as hemp, flax fibers or bio-based resins. In the laboratory, we research the mechanical properties and how the materials perform during the life cycle using. Therefore we use real bridge structures. In 2016 we designed and realised a pedestrian bridge made of bio-based fiber composite material in Eindhoven. We are currently working on the European Interreg research project “Smart Circular Bridge for a circular built environment” with 14 partners, in which we will build a total of three bridges made of bio-based fiber composite materials with integrated sensors that monitor the structural condition in real time by 2023. These materials definitely have the potential to transform the construction industry in terms of climate protection and resource conservation and can gradually reduce the use of concrete.